- Ranipet

- Sivakasi

- Karur

- Udhagamandalam

- Hosur

ROKADE RotoTechniks provides Infrared Thermography Services, comprising Survey of Electrical installations (Fuse units, Main Breaker / isolator Switches, Change over switches, Main Electrical panels, Distribution panels / boxes, Cable junction boxes, Capacitors / Insulators, Transformer / DG Alternator cable junction box, DC power systems (SMPS), UPS / Inverter distribution circuits terminals, MCC & PCC panel, switchgears, motor junction box terminal, switchyards etc.) and Mechanical equipment (Motor, pumps, compressor, blower, gearbox, bearings, turbines, pipe leakage, refractories etc.)

The infrared electrical systems survey locates problems before they lead to an unscheduled outage, equipment damage or a fire.

Our team consisting of professional experts carry out High Quality Thermography Testing activities of any magnitude, to the entire satisfaction of the Clients.

An infrared electrical systems survey scan can substantially improve profitability and reduce your operating, testing and maintenance costs by offering the following benefits

Quickly pinpoints electrical systems problems

Reduces downtime and electrical equipment damage

Prevents catastrophic and costly system failures

Allows engineers and facility managers to establish repair priorities

Drastically improves preventive maintenance efficiency

Can be tested under load to avoid costly system shutdowns

Infrared thermography services are a valuable tool for condition monitoring and preventive maintenance. Not only does it allow you to detect thermal abnormalities of machines, but it lets you do so in a non-intrusive, hands-off way while still getting results in real-time.

Thermographers usually employ one of three methods when performing thermal inspections: Comparative, Baseline and Thermal Trending. Determining which method to use comes down to the type of equipment you're testing and the type of data you want to

Comparative Thermography

Comparative thermography is used to measure the temperature of similar components under similar conditions. By comparing the results, useful information about the components' condition is obtained, thanks to the uncovering of hidden problems. Comparative thermography comparisons can be quantitative or qualitative. Quantitative inspections measure precise temperature and/or temperature distribution and are typically performed by a highly trained thermographer.

Qualitative inspections focus on the differences in temperature rather than actual temperatures. Nearly all (90 percent) industrial and mechanical applications for modern thermography are qualitative, but using quantitative measurements in tandem with qualitative measurements can help determine the severity of the condition as well as the problem itself.

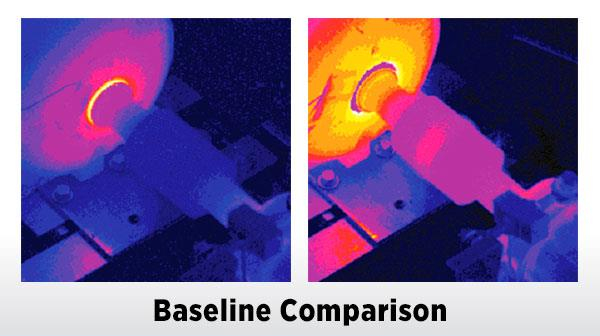

Baseline Thermography

Baseline thermography is used to set a precedent or establish a reference point for an asset by taking temperature readings when the asset is in good working order. It is used in comparison with other thermal images to identify potential issues early. It's recommended to take baseline measurements on all critical assets when they are new or have just been repaired.

Thermal Trending Thermography

Just as trends show changes over time, thermal-trending thermography shows how temperature is dispersed in a component or asset over time. It's a great method for looking at mechanical equipment with complex thermal signatures or when thermal signatures develop slowly. A great example of using thermal trending is monitoring high-temperature refractory insulation in a boiler over time to help determine a proper maintenance schedule that minimizes downtime.

TAMIL NADU

ANDHRA PRADESH

KARNATAKA

KERALA

TELANGANA

MAHARASHTRA

GOA

GUJARAT

UTTAR PRADESH

DELHI

RAJASTHAN

PUNJAB

HIMACHAL PRADESH

HARYANA

UTTARAKHAND

WEST BENGAL

ODISHA

JHARKHAND

BIHAR

MADHYA PRADESH

CHHATTISGARH